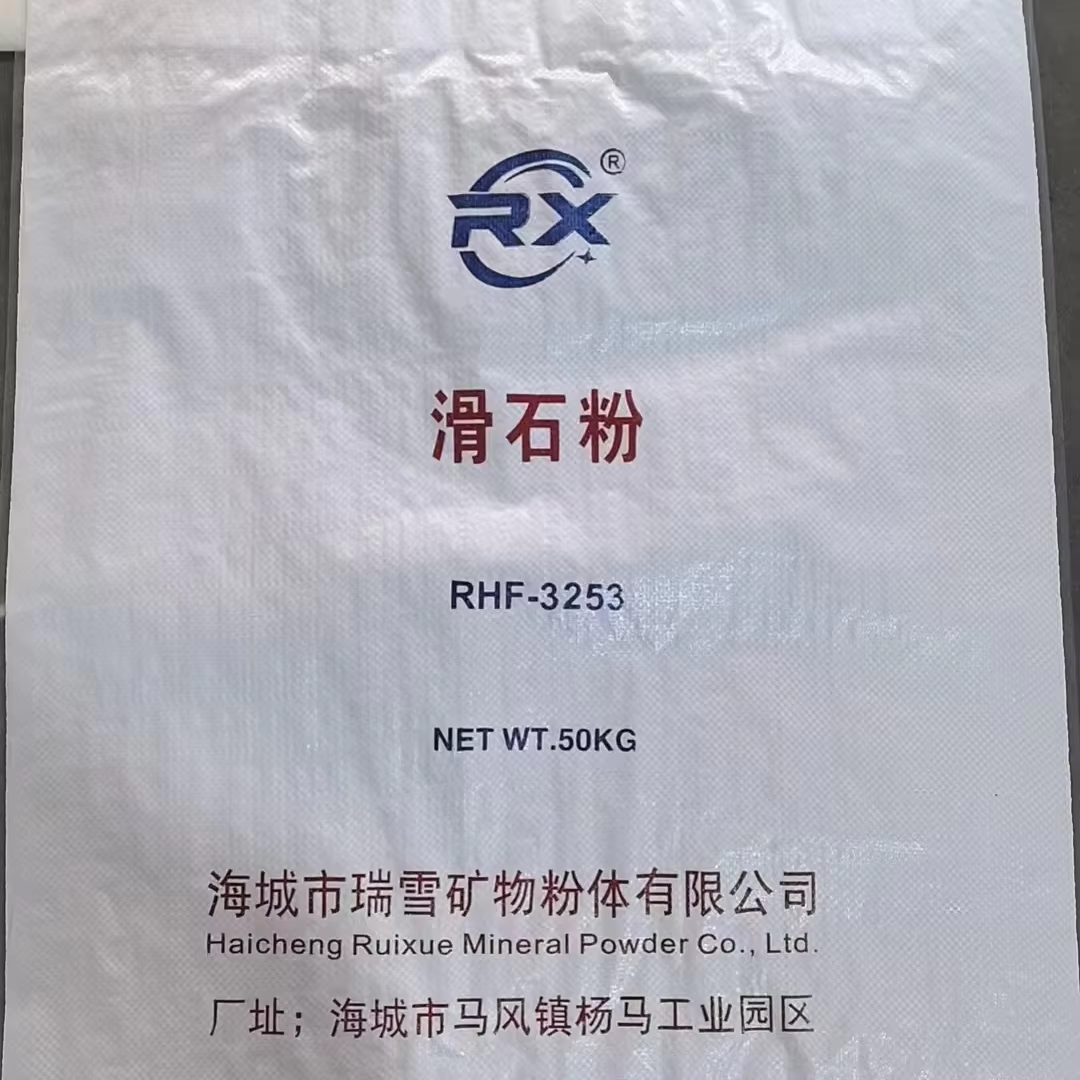

煅烧滑石粉是一种以天然滑石矿石为原料,经高温烧结加工而成的高性能材料。这种优质产品即使在1300°C的极端条件下仍能保持94-95%的优异白度,是高温应用的理想选择。煅烧工艺显著提升了材料的热稳定性和力学性能,能有效增强陶瓷坯体及其他复合材料的韧性和耐热性。凭借其卓越的耐热性和均匀的颗粒分布,煅烧滑石粉广泛应用于陶瓷、塑料、橡胶、涂料等工业领域,可显著减少产品变形、提高尺寸稳定性,并全面增强最终制品的耐久性。

Fixed calipers by Wilwood offer unmatched stopping power. The pistons in fixed calipers are located on both sides of the disc, allowing for evenly distributed clamping force. They apply more squeezing power and apply it more evenly during braking as force is directly applied to both sides. Multi-piston calipers allow for more even braking and, as a result, less pad distortion. The more number of pistons a caliper has, the more clamping force it provides. Thanks to the evenly distributed pressure, these calipers ensure an even wear pattern along the entire length of the brake pad. Usually these calipers have smaller diameter pistons than single-piston calipers.

The internal vane design of these vented rotors by Wilwood provides excellent heat dissipation during brake cycles. As the wheel spins, the vanes around the edge of the rotor draw air in and pull it through to help cool the rotor. With the extra heat dissipated there will be less brake fade. This rotor design by Wilwood combines the best features of a slotted rotor and cross-drilled rotor allowing your brakes to run cooler and sweep away water and dust. The cross-drilled and slotted rotors improve air circulation and increase brake pad bite, ensuring incredible stopping performance.